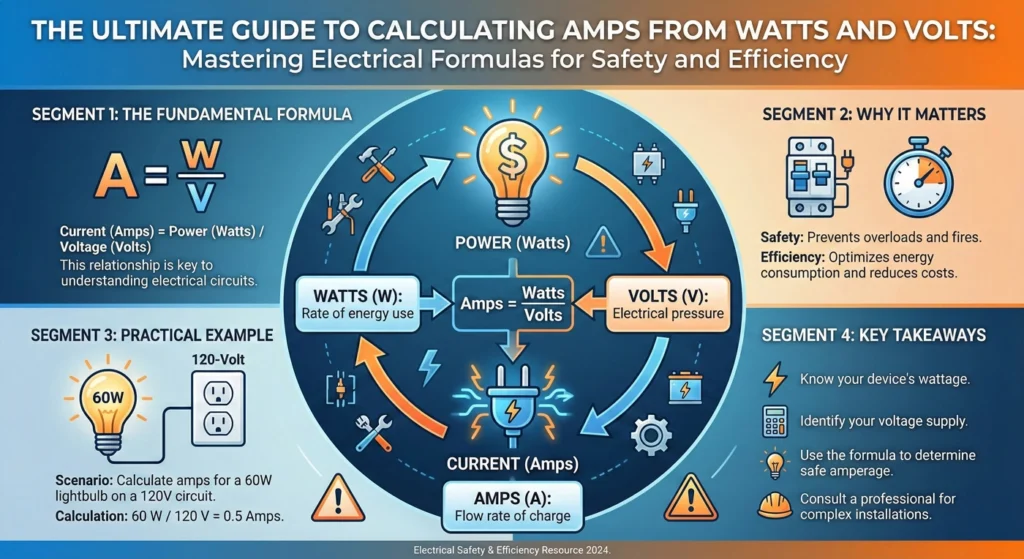

So here’s the thing – electricity is literally everywhere in our lives, right? From your phone charger to your microwave to that gaming rig you’re secretly planning to upgrade. But have you ever wondered if your circuit can actually handle all the stuff you’re plugging into it? That’s where knowing how to calculate amps becomes super important.

Look, I’m not trying to turn you into an electrician or anything, but understanding current (that’s what amps measure, by the way) is honestly essential. It helps you avoid overloading circuits, choose the right wires and outlets, and basically keep your house from, you know, catching fire. Not to be dramatic or anything, but electrical safety is no joke!

In this guide, I’m gonna walk you through everything you need to know about calculating amps from watts and volts. And don’t worry – I’ll keep it simple and actually useful.

Quick Answer (For Those in a Hurry):

Want the TL;DR version? Here it is: To calculate amps in a basic DC circuit, just divide your watts (power) by your volts (voltage). Boom. That’s it. For AC systems, there’s a tiny bit more to it because of something called power factor, but we’ll get to that in a sec.

The Electrical Fundamentals: Defining Key Units

Okay, before we dive into the formulas and calculations, let’s make sure we’re all on the same page about what these electrical terms actually mean. Trust me, this’ll make everything else way easier to understand.

What is Ampere (Current)?

Think of amperage (or amps for short) as the amount of electrical flow moving through your wires. It’s like water flowing through a pipe – the amp measurement tells you how much electricity is actually flowing at any given moment. When you’re calculating amps, you’re basically figuring out how much electrical current your device or circuit is using.

The official unit is the ampere, named after some French physicist guy. But honestly, everyone just says “amps” because we’re all busy people.

What is Voltage?

Voltage is the electrical pressure or potential difference in your circuit. Going back to that water analogy – if amps are the flow of water, voltage is the water pressure pushing it through the pipes.

In the US, most household outlets are 120 volts (though some big appliances use 240V). If you’re off-grid or into RV life, you might be dealing with 12V or 24V systems. Different strokes for different folks!

What are Watts (Power)?

Watts measure the actual power – how much energy your device is consuming or producing. When you see a 60W light bulb or a 1500W space heater, that number is telling you the power consumption.

Here’s where it gets cool: watts, volts, and amps are all connected through some neat mathematical relationships. It’s all tied together by something called Ohm’s Law, which sounds intimidating but is actually pretty straightforward once you get it.

Core Calculation: Amps from Watts

Alright, this is where the magic happens. Let’s talk formulas!

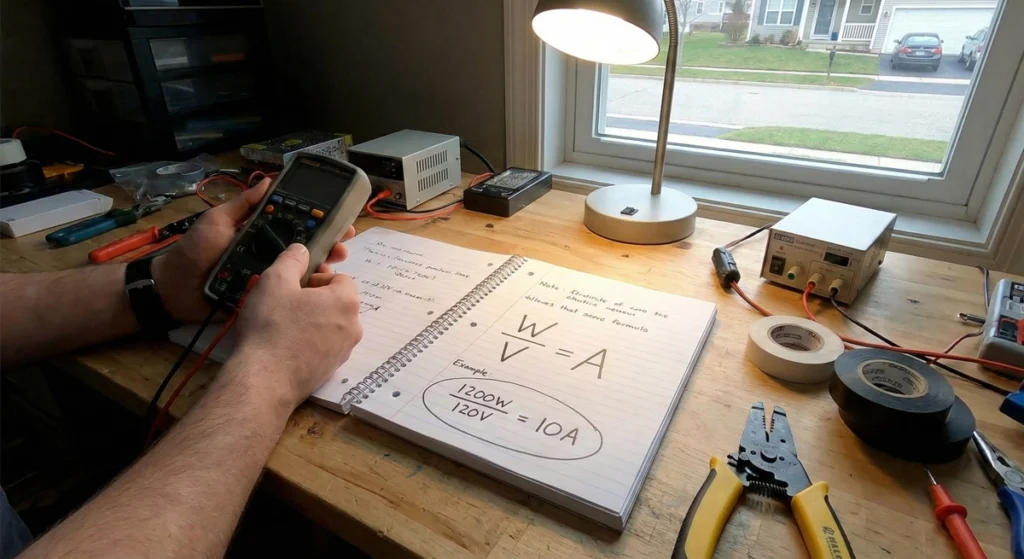

The Master Formula

The fundamental relationship you need to know is this:

Power (P) = Voltage (V) × Current (I)

Or in plain English: Watts equals volts times amps. This is your new best friend.

Calculating Amps in DC Circuits

For DC (direct current) circuits – like batteries, solar panels, or anything running on DC power – the calculation is super simple. Just flip that master formula around:

Amps (I) = Watts (P) ÷ Volts (V)

That’s it! You take your wattage, divide it by your voltage, and boom – you’ve got your amperage. Easy peasy.

For example, let’s say you’ve got a 100-watt device running on a 12-volt battery. The calculation would be: 100W ÷ 12V = 8.33 amps. See? Not so scary.

Calculating Amps in Single-Phase AC Circuits

Now, AC (alternating current) circuits – like your house electricity – have one extra little twist. There’s this thing called power factor that you need to account for. The formula looks like this:

Amps (I) = Watts (P) ÷ (Volts (V) × Power Factor (PF))

So what’s this power factor thing? Basically, in AC circuits, not all the power is being used efficiently. Some of it gets stored and released in the circuit (it’s a whole physics thing with magnetic fields). The power factor is a number between 0 and 1 that represents how efficiently the power is being used.

For most household stuff, you can assume a power factor of around 0.8 to 1.0. Resistive loads (like heaters and incandescent bulbs) are usually close to 1.0, which makes the math easier.

Calculating Amps in Three-Phase AC Circuits

Okay, this one’s for the advanced folks – or if you’re dealing with industrial equipment or big commercial setups. Three-phase power is more efficient for large-scale operations, but the formula is a bit more complex:

Amps (I) = Watts (P) ÷ (√3 × Volts (V) × Power Factor (PF))

That √3 (which is about 1.732, if you’re wondering) comes from the way three-phase power is distributed. Unless you’re working with industrial equipment or running a business, you probably won’t need this one too often.

Step-by-Step Practical Application

Theory is great and all, but let’s get practical. Here’s how you actually use this stuff in real life when you’re calculating amps for your devices.

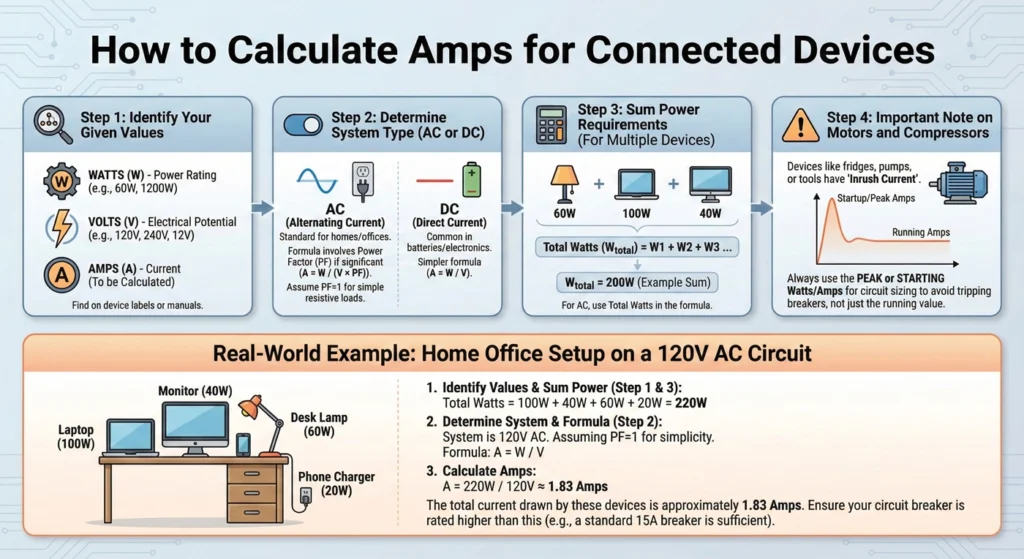

How to Calculate Amps for Connected Devices

Step 1: Identify Your Given Values

First things first – find out the wattage and voltage of whatever you’re working with. For most devices, there’s a label somewhere (usually on the back or bottom) that tells you this info. It might say something like “120V, 1500W” or “12V DC, 60W.”

Step 2: Determine System Type (AC or DC)

Figure out if you’re dealing with AC or DC power. This determines which formula you’ll use. Most household outlets are AC, while batteries and solar setups are typically DC.

Step 3: Sum Power Requirements (For Multiple Devices)

Here’s where it gets real interesting. Let’s say you want to know if you can safely run multiple devices on the same circuit. You need to add up all the wattage first, then calculate the total amperage.

Real-World Example:

You’re setting up your home office and want to plug everything into one power strip. Here’s what you’ve got:

- Two laptops (95W each)

- A TV (75W)

- A monitor that you know draws 1.0 amp

First, add up the watts: (95 + 95 + 75) = 265 watts

Now divide by your voltage (let’s say 120V for a standard US outlet): 265W ÷ 120V = 2.21 amps

But wait! Don’t forget that monitor that’s rated in amps already. Add that in: 2.21 + 1.0 = 3.21 amps total

So you’re pulling about 3.21 amps total. Most household circuits are 15 or 20 amps, so you’re totally fine! You’ve got plenty of headroom.

Step 4: Important Note on Motors and Compressors

Here’s something that trips people up all the time: motors and compressors (like in air conditioners, refrigerators, or power tools) need way more current when they first start up. We’re talking like 3 to 5 times their normal running amperage, but only for a few seconds.

So if you’re calculating for something with a motor, remember that your circuit breaker needs to handle those startup surges. This is why refrigerators sometimes trip breakers when they kick on if you’ve got too much other stuff running on the same circuit.

High-Value Reference Table: Amps, Watts, and Volts Conversion

Let me drop a handy reference table here for quick lookups. These are for DC circuits (remember, AC would need you to factor in that power factor):

12V System:

- 100W = 8.3 amps

- 500W = 41.7 amps

- 1000W = 83.3 amps

24V System:

- 100W = 4.2 amps

- 500W = 20.8 amps

- 1000W = 41.7 amps

120V System:

- 100W = 0.83 amps

- 500W = 4.2 amps

- 1000W = 8.3 amps

- 1500W = 12.5 amps

Notice how higher voltage systems use fewer amps for the same wattage? That’s actually a really important concept we’ll talk about next.

Critical Safety and Efficiency Considerations

Okay, now that you know how to calculate amps, let’s talk about why it matters so much for safety and efficiency.

Wire and Cable Sizing Based on Amperage

Here’s the deal: when electricity flows through a wire, it creates heat. The more amps flowing through, the more heat gets generated. If you use a wire that’s too thin for the amperage you’re pushing through it, that wire can overheat and potentially start a fire. Yikes.

This is exactly why calculating amps helps you choose the right wires and outlets for your setup. Every wire gauge has a maximum amperage rating. For example:

- 14-gauge wire: good for up to 15 amps

- 12-gauge wire: handles up to 20 amps

- 10-gauge wire: can carry 30 amps

If you’re setting up an off-grid solar system or building out an RV electrical system, you absolutely need to get your wire sizing right. Don’t cheap out here – proper wiring isn’t just about following code, it’s about not burning your house down.

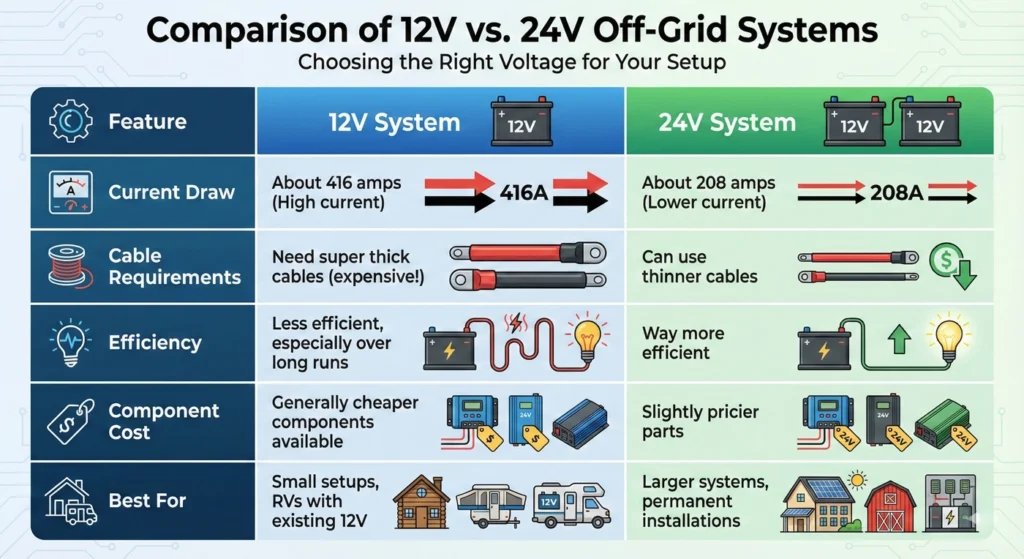

Comparison of 12V vs. 24V Off-Grid Systems

For all my off-grid friends out there (or aspiring van-lifers), this section’s for you. When you’re setting up a battery system, one of the big decisions is whether to go 12V or 24V. Let me break down the differences:

5000W System Comparison:

| Feature | 12V System | 24V System |

|---|---|---|

| Current Draw | About 416 amps | About 208 amps |

| Cable Requirements | Need super thick cables (expensive!) | Can use thinner cables |

| Efficiency | Less efficient, especially over long runs | Way more efficient |

| Component Cost | Generally cheaper components available | Slightly pricier parts |

| Best For | Small setups, RVs with existing 12V | Larger systems, permanent installations |

See how the same 5000 watts requires way fewer amps in a 24V system? That’s the beauty of higher voltage – less current means thinner (cheaper!) cables, less heat, and better efficiency. This is why your house uses 120V or 240V instead of 12V!

For anything over about 1500 watts, seriously consider going 24V. Your wallet (and your cables) will thank you.

Common Calculation Pitfalls to Avoid

Let me save you from some mistakes I see people make all the time when calculating amps from watts and volts:

Mistake #1: Getting Your Numbers Wrong

This sounds obvious, but double-check whether that number on your device label is watts or amps. Sometimes manufacturers list one, sometimes the other, sometimes both. Mix these up and your whole calculation is toast.

Mistake #2: Looking at the Wrong Side of Power Adapters

Those power brick adapters (like for laptops) have ratings on both the input and output sides. If you’re trying to figure out what you’re pulling from the wall outlet, you need the INPUT side – not the output! The output is what goes to your device, but that’s a different voltage and amperage.

Mistake #3: Trusting Label Ratings Too Much

Device labels usually show the maximum power draw – like when the device is working its absolute hardest. In reality, most gadgets don’t constantly pull their rated wattage. Your laptop might be rated for 95W, but it’s probably only using 30-40W most of the time (unless you’re gaming or rendering video).

When planning circuits, it’s smart to calculate based on the label ratings to be safe, but just know that your actual usage is probably lower.

Conclusion

Look, I get it – all this talk about volts and watts and formulas might seem like overkill. But honestly? Understanding how to calculate amps is one of those life skills that’s way more useful than you’d think. Whether you’re:

- Trying to figure out if you can run that space heater and your gaming PC at the same time

- Setting up a solar system for off-grid living

- Just wanting to be a more informed homeowner

- Planning an RV electrical system

…knowing how to do these calculations keeps you safe and saves you money. Plus, you get to feel like a smart cookie when your friends are confused about why their circuit breaker keeps tripping.

The key takeaway? It’s all about that simple relationship: Amps = Watts ÷ Volts (with a few tweaks for AC circuits). Master that, and you’re golden.

Want to Learn More?

If you’re hungry for more electrical knowledge, check out these related topics:

- Deep dive into Ohm’s Law

- Understanding the difference between amps and volts (and why both matter)

- How to choose the right wire gauge for any project

- Power factor explained (for the AC nerds)

- Signs your battery is dying (spoiler: it’s more than just “it doesn’t work”)

And hey, if you found this guide helpful, subscribe to stay updated on all things power, batteries, and electrical systems. We’ve got tons more tips and tricks coming your way!

Stay safe out there, and happy calculating!